The food industry is evolving rapidly. Consumers expect greater product variety, healthier formulations, and sustainable production. At the same time, the need for process optimization is increasing: higher efficiency, consistent product quality, and reduced waste. In this context, the food industry can learn a great deal from pharmaceuticals, where continuous dosing of solids has long been standard practice.

In pharmaceutical manufacturing, accuracy, reproducibility, and hygiene have been leading principles for decades. Dosing and mixing systems are designed to reliably handle a wide range of ingredients. This experience is proving relevant to today’s challenges in food processing.

Anyone involved in dosing solids in the food industry knows that every ingredient behaves differently. Think of milk powder, cocoa powder, apple fiber, sugar, herbs, nuts, rice crisps, or salt. Common challenges in continuous dosing include:

It is therefore essential to match the dosing system to the specific characteristics of each ingredient. Just as in pharmaceuticals, this requires a customized approach based on the bulk material properties of every product.

In continuous food dosing, a modular, pharma-inspired approach is increasingly proving its value. In practice, four building blocks determine process stability:

Together, these elements ensure a reproducible dosing process, even with difficult-flowing or highly variable ingredients.

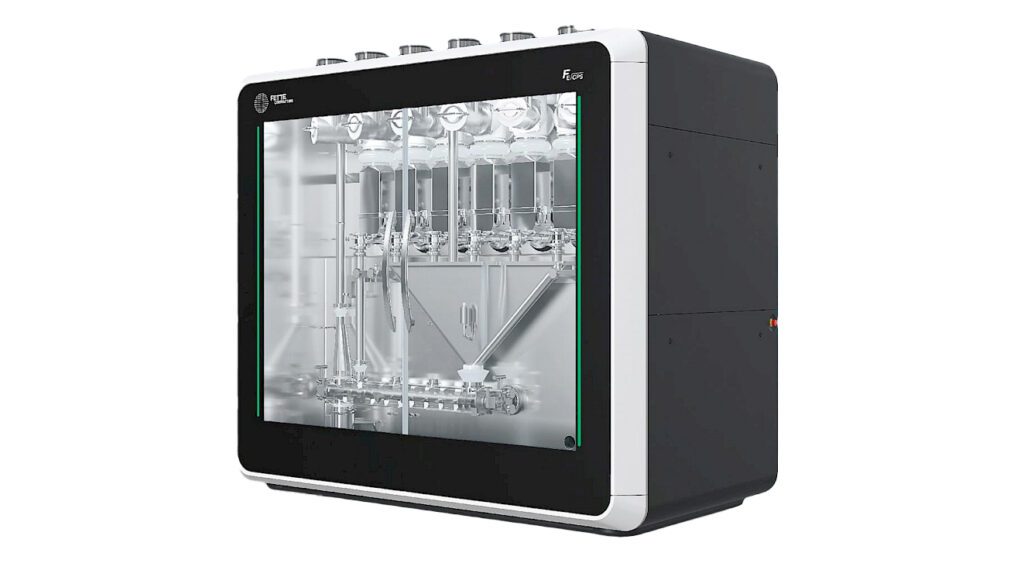

A strong example of technological cross-fertilization between pharma and food is the FE CPS dosing unit. This modular dosing and mixing system was developed by Fette Compacting and Kubota Brabender Technologie for pharmaceutical applications and is equally well suited for food production lines where consistent quality and recipe flexibility are essential, and where a wide variety of ingredients with different bulk material characteristics must be processed.

System features:

– Fully modular design

– Gravimetric control

– Fast cleaning and screw exchange

– Suitable for powders, granulates, fibers, flakes, and pellets

Thanks to this flexibility, the system can be applied across a wide range of recipes and production runs, enabling accurate dosing and mixing of multiple solid components.

Curious how such a system works in practice? Watch the short video on the FE CPS dosing unit to see how accurate, continuous dosing of food ingredients is achieved.

Conclusion

What can the food industry learn from pharmaceuticals? That a well-considered approach to accurate, flexible, and easy-to-clean dosing systems is essential to prevent process disruptions and achieve a robust, reproducible production process. Exactly what is needed for short production runs, strict hygiene requirements, and an ever-growing variety of ingredients.

More information or advice?

Contact SPS | Solids Process Solutions for practical examples, technical support, or a system demonstration.