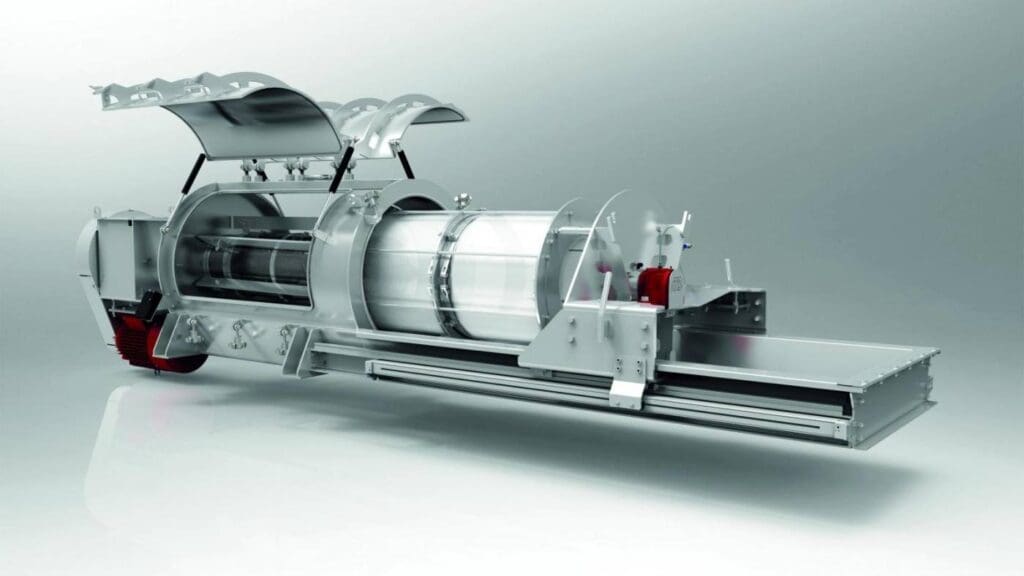

Developing a new sifter with improved inspection methods to prevent cross contamination was a challenging task that Dinnissen was happy to accept. Thanks to the extensive experience and expertise, the engineers at Dinnissen developed the Wingdoor sifter; a perfect combination of innovative power and the sieving process. The major advantage of this machine is that the doors can now open over the entire length of the machine. Therefore, the sieve does not need to be driven out for inspection, so that cross contamination is prevented. The replacement of the sieve mesh is naturally very efficient because the sieve basket can still be slide out of the machine. In addition, the Wingdoor sifter can reach capacities up to 30 tonnes per hour depending on the product.