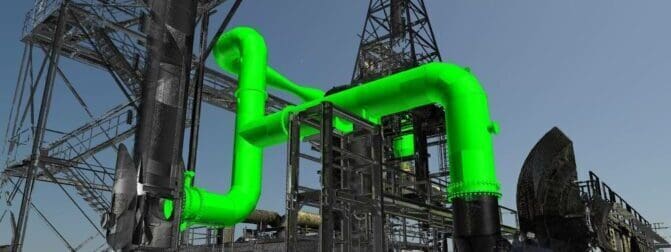

The Lybover group is fully committed to 3D scanning technology. With additional investments and a dedicated scanning team, Lybover is shifting up a gear in 2020. Lybover’s extensive experience in engineering, project management, production and assembly combined with 3D scanning and engineering has a huge impact on time, cost and safety. This is why 3D scanning has been the basis for engineering all kinds of projects at Lybover for many years.

On the wings of engineering

Lybover has a team of 80 engineers working in various sectors. The various business units build installations in numerous sectors for which the basis of the engineering is provided by 3D scanning. More than 100 projects have already been successfully delivered in this way.

Meanwhile, 3D scanning is presented to customers as standard. With 3D scanning, the cost price is at least identical but in many cases even more advantageous than with manual measurement. Add to this the additional benefits and the choice is quickly made. “In our experience, 3D scanning is always advantageous,” says Filip Boels, CEO of Lybover. We save time and money and gain safety.

Impact on time, cost and safety

“The benefits are many,” confirms Yves Vandenhende, Head of Production / Head of Projects at Lybover METAL. “We measure faster and more correctly. The pre-engineering is more complete. No rework or surprises during assembly. Fewer measurements at height and less presence on site increase safety.”

Still, 3D scanning and all the possibilities associated with it are not that well known yet. “We want to change that this year. Through a series of seminars and an information campaign, we want customers and potential customers to discover the benefits of 3D scanning and engineering,” concludes Filip Boels.